CEA CESTA designs the nuclear warheads used for deterrent purposes. One of its responsibilities is to provide the guarantee that the nuclear warheads are safe and fulfil their objectives in terms of their resistance to mechanical and thermal environments, invisibility to radars, ability for atmospheric re-entry and so forth. “There is no room for uncertainty in our business given the strategic importance of the objects that we engineer. We have extremely stringent levels of requirements in all areas”, explained Eric Chauvet, design engineer at CEA CESTA. Naturally, this high level of requirements also extends to the threaded and bolted subassemblies. “For many years, we have drawn on the expertise of Cetim which has significant human and technical resources as well as broad experience in the area”, outlined Eric Chauvet. Cetim regularly carries out test campaigns on its instrumented benches to characterise the threaded connections entrusted by CESTA.

Several types of screws and bolts

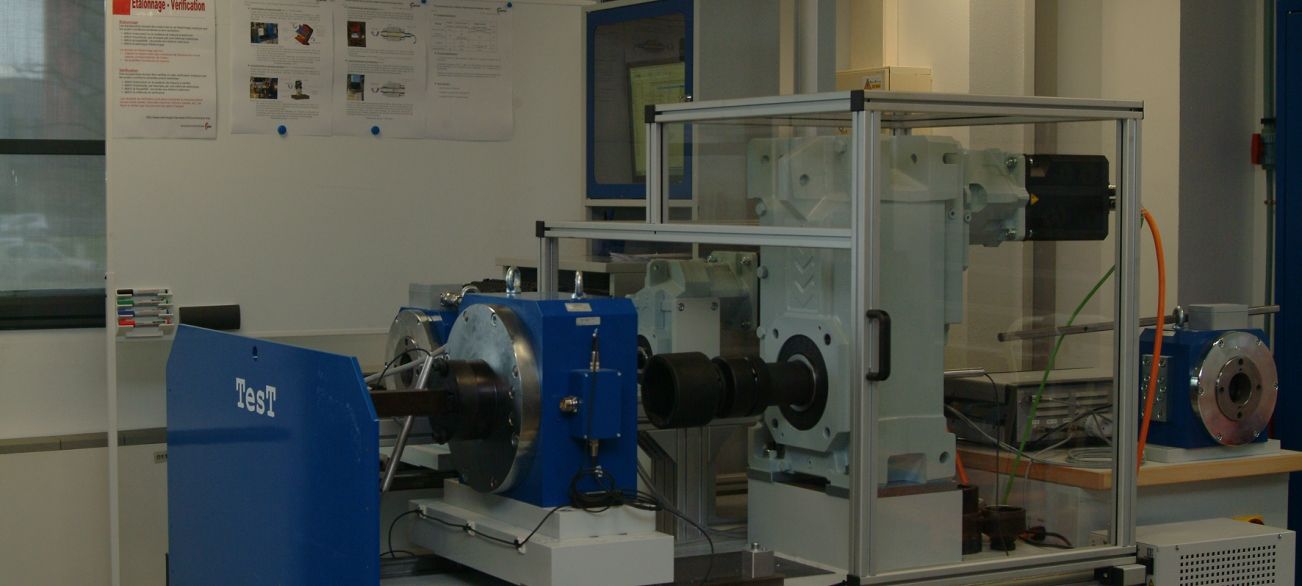

The tests relate to several types of screws and bolts with varying diameters, lengths, materials and surface conditions. They are used to determine the friction coefficient in the threads, the torque/clamp force relationship, the friction coefficient at the interface of the clamped parts, the tightening instructions suited to each situation, etc. CESTA then uses the data from the measurements that represent real conditions, as input data in the Cetim Cobra software developed by Cetim for the sizing of threaded joints. The results obtained will then be used by the tools simulating the overall behaviour of the objects incorporating these threaded and bolted joints thereby guaranteeing maintained mechanical performance. “Overtime Cetim has proven to be an essential partner through its control of phenomena and its level of expertise. Cetim’s experts provide us with highly accurate analyses. They are responsive and are always willing to share both their certainties and their uncertainties”, added Eric Chauvet.