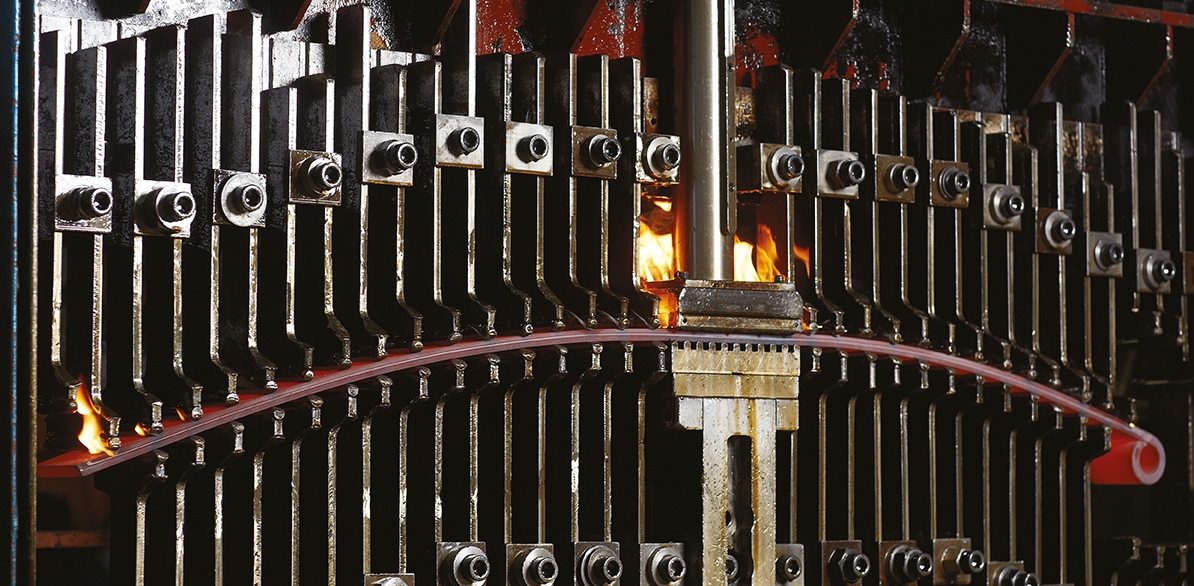

DPIA Colaert is a French manufactu-rer of suspension systems which supplies its products to major players in the rail sector. The company is located in Valence, Drôme, and markets a broad range of leaf springs and coil springs for the various trains across the world. "Our springs are fitted on freight convoys and rail maintenance vehicles as well as historical tourist trains such as the yellow train in the Pyrenees or the Mastrou train in Ardèche, explained Matthieu Giovanna,QSE Manager at DPIA Colaert. In order to be featured on these markets, our products must be type-approved by the train operator. Therefore, we often work with Cetim's experts who carry out metallurgical analyses and mechanical tests on many of our parts." These regular inspections also serve to guarantee the long term reliability of suppliers' products, whether the suppliers are new or established on the market.

Quick reaction

However, the company may also experience problems such as the detection of cracks on a leaf during operation, or even equipment failure. "In these circumstances, we have to be highly responsive and provide solutions within very tight deadlines at the request of our customer, added Matthieu Giovanna. Our credibility on our markets depends on this and this is why we are now calling on Cetim's experts who work well in emergency situations and provide technical explanations and unquestionable proof of who is responsible, based on their failure analyses." Metallurgical and mechanical analyses are carried out subsequent to a morphological examination of the damage. The goal is to understand the root cause of the failure and to recommend solutions as to the treatment of the parts during manufacturing by the various suppliers, during their maintenance or during operation.