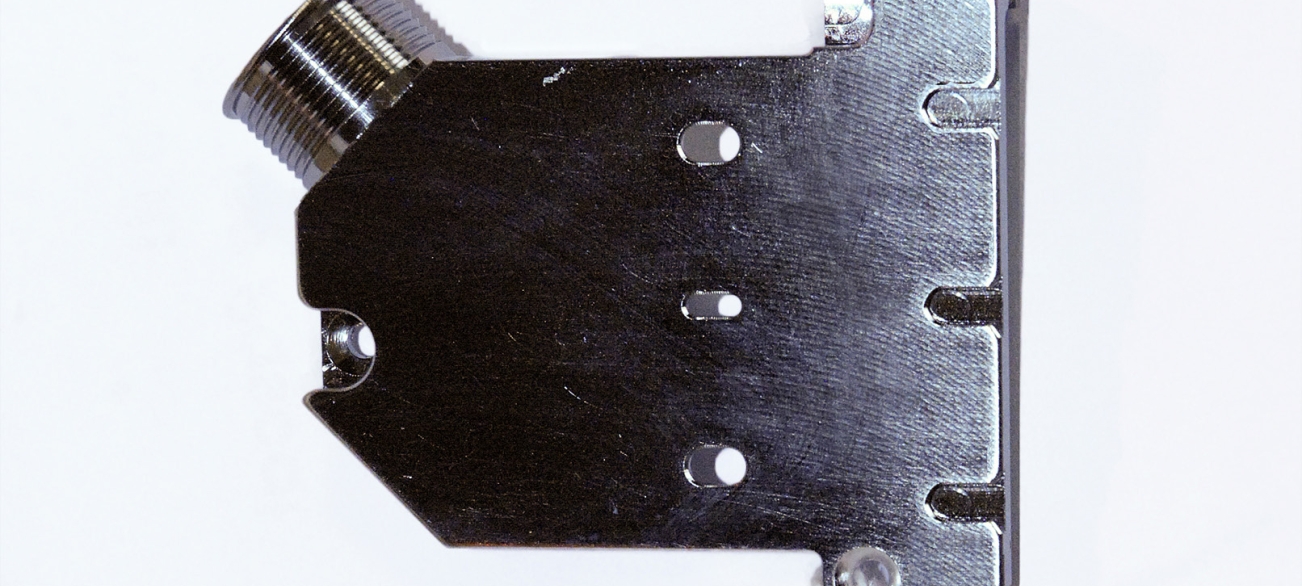

The aerospace industry does not settle for mere approximations! For its new AW 6082 T6 aluminium alloy units coated with a 25-micrometer thick Phosphorus chemical Nickel plating, Gauthier Connectique must perform tests to show compliance with its customers’ specifications. As a matter of fact, these units which are designed to be fitted on Airbus DS and Thales Alenia Space satellites have to undergo significant thermal shocks which instantly range from -50 to +120°C. As a result, it is essential under these conditions to check the proper resistance of the heat treatments: adhesion, magnetic impermeability, anticorrosion, etc. “Our products are subjected to numerous extremely severe tests in special climatic chambers, explained Thierry Paul, Environment Quality Manager at Gauthier Connectique. We wanted a laboratory that would be able to perform all the tests in order to check the proper resistance of the heat treatments carried out by our subcontractors. Further to a competitive tendering process, only Cetim committed to performing all the tests.”

Concerted efforts

The Centre’s experts leveraged on its technical and human resources and that of Cetim- Cermat, an associated centre located in Mulhouse (France) to successfully complete the tests in a very short period of time. A cross-hatch cutter test followed by a peel test with 3M masking tape were used to verify the adhesion of the plating. Damp heat and hot-cold cycling tests were then conducted in a climatic chamber in accordance with the international standard IEC 60068-2-78. “Cetim’s experts not only validated the heat treatments performed by our subcontractors, they also contributed with their expertise to the design of the product, added Thierry Paul. The tests performed helped us to qualify one of the candidate subcontractors and to win the contract with our customers in record time.” Other cooperations are in progress and a new subcontractor must be selected soon.