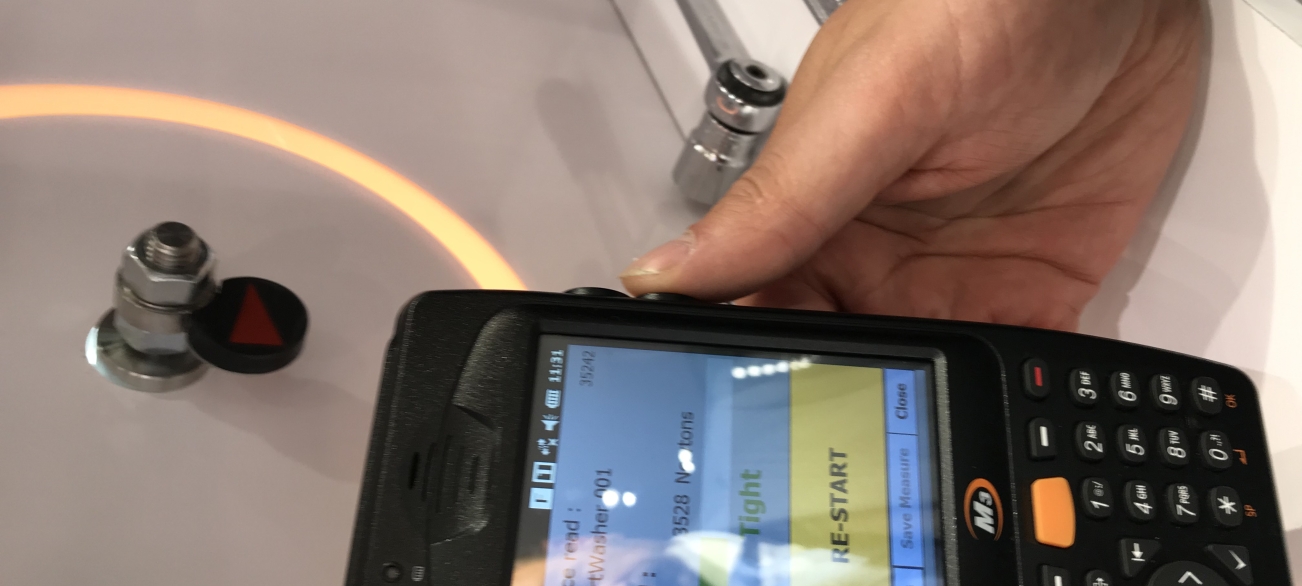

This is almost magic…With its latest innovation, JPB Système offers a means to ensure that a nut is properly tightened just by getting close and without touching it. The secret is a connected washer. “This washer is made up of a machined sensor body with gauges installed in it and a communication device associated with software installe don a portable device. The combination of all these items makes itpossible to measure the axial tensile load applied to the washer”, explains Jonathan Beaumel, design engineer at JPB Système. In order to prevent any electromagnetic problems, the designers opted for a remotelypowered passive system. Everything started in 2017, when one of JPB Système’s customers made an odd request, more precisely “a means to know at any time that a nut is properly tightened”. The solution is a combination of mechanics and Internet of Things (IoT), leading to a connected washer. JPB Système has strong skills in mechanics and software, but it decided to turn to Cetim for the mechatronics part. “The teams from Cetim’s mechatronics resource centre assisted us with the integration of the strain gauges and the electronics into the washer”, explains the design engineer.

A single technology, several prospects

The first version of the connected washer (M12 diameter) was presented for the first time during the Paris Air Show 2019 and proved its efficiency. “It displays the torque value in one second with anaccuracy of 6%, from a distance of 10 centimetres”, says Jonathan Beaumel. Even better, when scanning every nut equipped with this washer during the assembly operations, the instrument can accurately indicate all the improperly tightened nuts on a same engine. Further to the placing of the first model on the market in 2020, the company’s next objectives will be to extend the range of available diameters and to integrate this technology into other components. “In the end, we may integrate this technology into our nuts and borescope plugs in order to offer a connected option”, says Jonathan Beaumel.