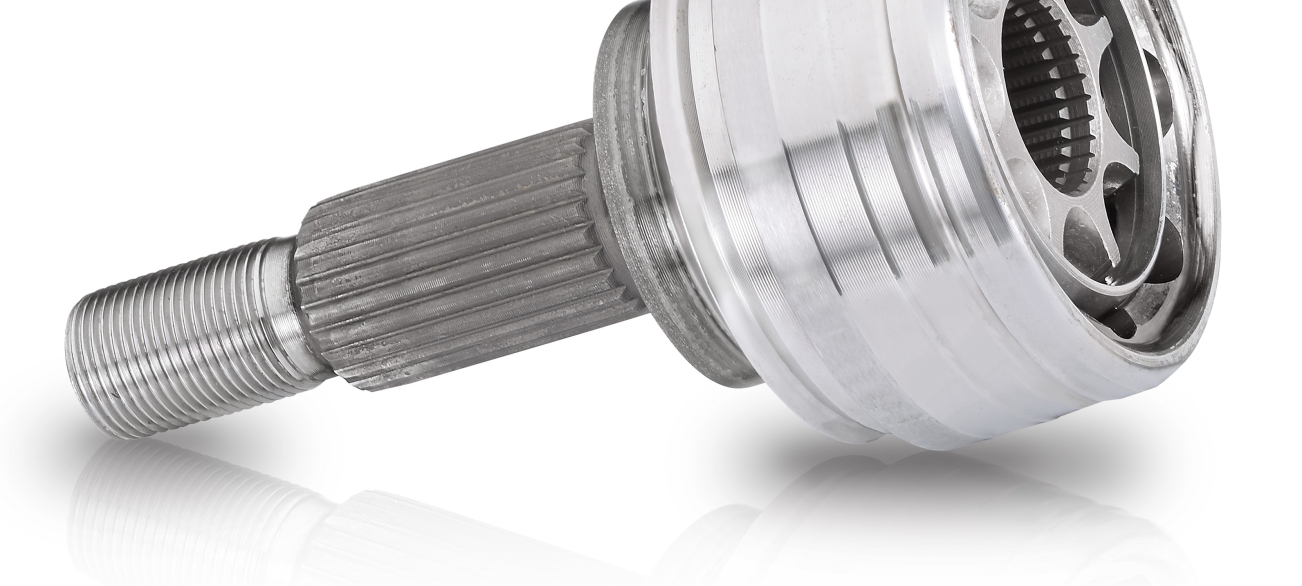

NTN Transmissions Europe is a company located in Allonnes close to Le Mans (Sarthe, France) which markets la-teral transmissions for the automotive sector. In this sector, equipment items are subjected to severe conditions which may cause fractures or distortions. The managers of the company called on Cetim in order to ensure the quality of the parts that they manufacture and gain a better understanding of the metallurgical factors involved in the part failures. Cetim was tasked with creating a specific in-house training programme combining both heat treatment and failure analysis. “Cetim offers two comprehen-sive modules in its training catalogue. One is a 14-hour module that features steels and their treatments and the other lasts 35 hours and covers the conduct of failure analysis: methodology, case studies of metal part fracture. Based on these two modules we wanted to obtain training on our premises for a shorter period of time and which consequently would be less time consuming for employees and more specifically suited to our products_”, explained Maxime Braut, Head of the Design Office.

Qualify and explain

Following examination, a four-day in-house training programme of two modules specifically designed for the company was offered. “Besides the reduced cost, this specific demand allowed us to centre the training on our productions and to study on site a practical case of failure which had been previously analysed by Cetim’s teams, added Maxime Braut. We carry out our own first level in-house analysis, however this training allowed us to take the process a step further with a thorough presentation of the failure analysis methodology and a practical approach of the experts’ know-how when confronted with a fractured part. Our employees were therefore able to see first-hand how the experts go about qualifying a failure by morphological fracture analysis and to explain this process. At the end of the day, we are extremely satisfied with Cetim’s approach. The centre was able to tailor its services to our requirements and we have already scheduled other training sessions of this type, such as surface treatment in particular.”