Lightweight, carbon-neutral and easy to store, hydrogen is being called on to play a key role in meeting global demand for cleaner energy. Subsurface storage solutions, such as salt caverns, appears to be a viable solution for storing hydrogen. However, the leak-tightness of connections must be tested to ensure that no gas escapes from the wells. Vallourec solutions have all been validated for oil and gas industry fluids for years. "Our metal-to-metal screwed connections ensure an extremely high level of leak-tightness,” declares Pierre Martin, R&D Manager at Vallourec. “We have demonstrated this with tests using nitrogen and helium. We want to ensure that the same holds true for hydrogen."

Test-specific methodology

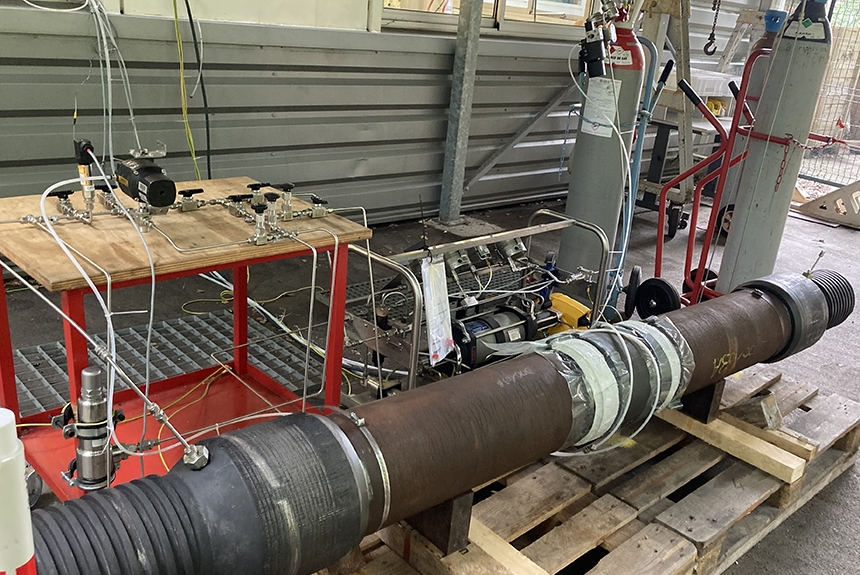

Since Vallourec lacks the required authorizations for safely conducting tests on this highly flammable gas, these were entrusted to Cetim who works closely with INERIS (the French institute for industrial environment and risks) to set up procedures ensuring hydrogen test safety. “Moreover, Cetim offers solutions able to measure low concentrations of hydrogen,” adds Pierre Martin. Therefore, a methodology adapted to the needs of this challenging medium was deployed. A mass spectrometer was used in sniffing mode to measure the concentration of hydrogen which could build up inside a flexible enclosure surrounding the connection being tested. This allows for considerably higher sensitivity than the traditional method. Full-scale testing performed on 245 mm (9-5/8”) samples at a pressure of 180 bars, then at 470 bars, validated leak-tightness of the tested connections. “No leak was detected despite the high accuracy of the leak detection systems at Cetim,” concludes Pierre Martin. In addition, testing was performed at various concentrations ranging from 5% to 100% hydrogen and the results were identical. To optimize safety, Vallourec will then pursue its analyses by carrying out, with its own means, combined tests using a gas mixture with 5% hydrogen.