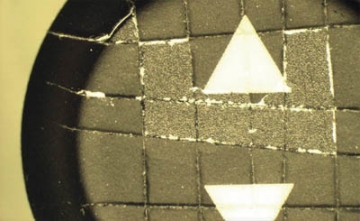

Was the corrosion affecting Alstom Power’s cabinets caused by a paint problem or an exogenous reason? The industrial company found the answer, strengthened its investigative powers and provided recommendations.

Understand and anticipate plastic, composite and elastomer material breaks