NDT, as a preventive measure, according to regulations or subsequent to a failure

Expertise in Non-Destructive Testing (NDT)

Your expectations

You want to automate/robotize your production control, inspect your equipment or get an external opinion on a metal, composite or multi-material product and you need :

- A solution to automate or robotise the “in line” testing on one or more stations of a production line

- A solution to detect or characterise defects

- An expert investigation or a confidential second opinion from a neutral organisation

- To have standard tests carried out by certified technicians

- To comply with standards and codes or update your compliance

Our solutions

Cetim supports you on all or part of a global value chain, from the definition of functional and organic specifications to the ‘industrial’ control solution

- Based on an analysis of your requirements, recommendations regarding the most appropriate testing method, from amongst a panel of conventional or innovative techniques (ultrasonic imaging, TOFD, ultrasonic phased array testing, active infrared thermography and guided waves...).

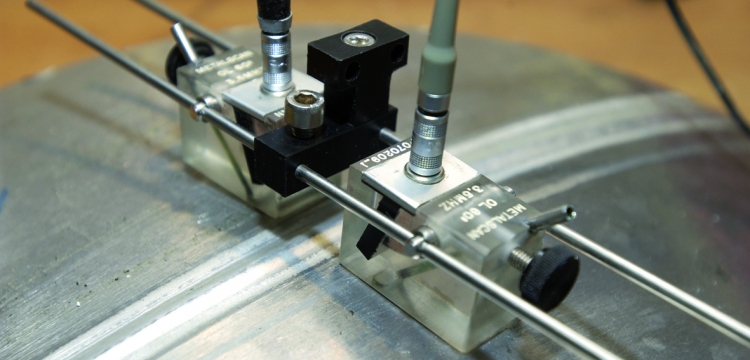

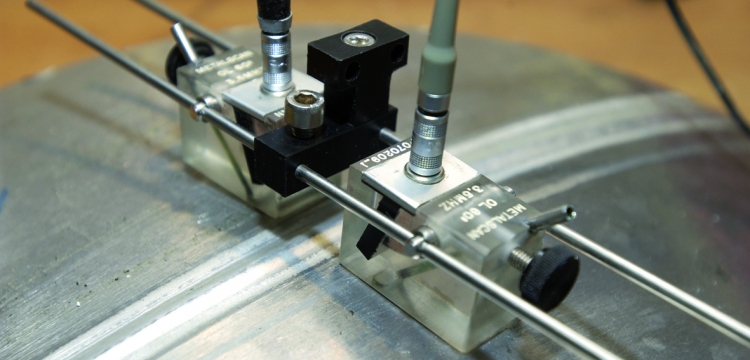

- Carrying out feasibility tests using digital simulation or mock-ups, design of testing equipment, probes, supports, optimisation of testing parameters via simulation or on standard parts

- Preparation of specifications for the automated testing system, identification of suppliers, monitoring of performance, acceptance, support and training for your staff

- Design and optimisation of tests using simulation software

- Performance of tests by COFREND-certified technicians (CIFM and COSAC) in methods such as penetrant testing, magnetic particle testing, ultrasonic testing, Eddy current testing, acoustic emission testing and X-ray testing.

ZOOM ON HYDROGEN

HyMEET, our technological platform dedicated to H2, provides mechanical engineering with resources and skills needed to master low-carbon hydrogen production, distribution, storage and utilization technologies. HyMEET combines an ambitious R&D program with a €25 million investment in resources dedicated to characterization and validation tests (up to 1000 bar and in a range of temperatures from deep cryogenics to high temperatures) as well as consulting and training.

Its activities are dedicated to:

- Characterizing the behavior of materials in contact with hydrogen

- Development of specific test methods

- Characterization of specific mechanical equipment and systems in severe hydrogen environments.

Our equipment enables:

- Mechanical characterization of materials using fatigue machines in a high-pressure hydrogen environment

- Control of sealing systems and plant containment, with test benches developed to study gas diffusion phenomena, resistance to rapid decompression and sealing performance under severe conditions

- The study of the ageing of test specimens in high-pressure autoclaves

- Tests under cryogenic conditions for the use of hydrogen in liquid form, with several cryostats fed by a helium-hydrogen liquefier

- Multiphysics tests with pressure, temperature and .... cycling.

- Manufacture of thermoplastic composite parts (tanks, tubes) by in-situ deposition and consolidation (in real time, with no further steps required) using our HySPIDE TP robotized cell.

Our specific services dedicated to H2 equipment :

- Monitoring of manufacturing processes and final inspections

- NDT of type IV tanks (US, tomography)

- Characterisation and monitoring of performance under operational conditions (burst tests, acoustic emission, etc.).

Your benefits

- Methods specifically tailored to your context, as several testing methods can be used during the same service

- Deliverables: an automated/robotised testing system, a detailed and explicit report with potential proposals for corrective actions (failure analysis, redesign, etc.)

- Cetim is an independent organisation