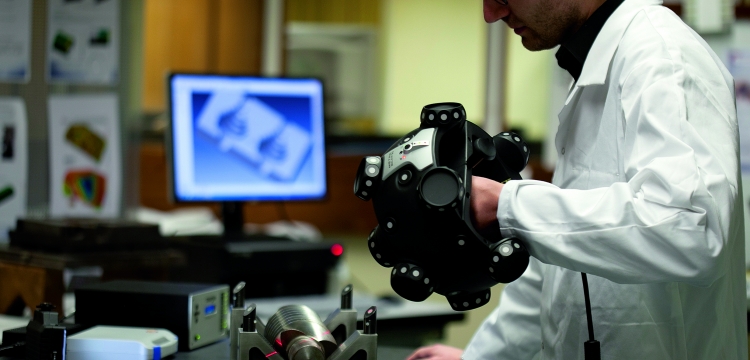

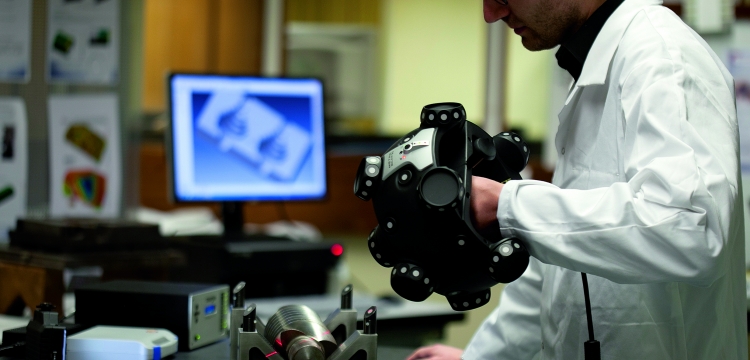

3D scanning, inspection and reverse engineering of products (all materials).

Scanning / Reconstructing your products in 3D

Your expectations

You are looking for an independent and impartial service provider for the following purposes:

- Scanning and reverse engineering of your products.

- Quality control, 3D inspection, geometrical and dimensional characterisation of your components, through comparison with the digital definition (CAD file).

- Drawing up of “as built” 3D documents of infrastructure and related facilities, pipes, buildings, assemblies and subassemblies of all types of materials.

- Alignment and calibration of machines, robots, assemblies and structures.

- Creation of 3D digital models.

- Failure analysis, reconstitution of damage and accidents, detection and elimination of collision and alignment errors.

- Virtualisation of sceneries, characters, artworks for films and video games.

Our solutions

CETIM offers you a local measuring service from its three laboratories in France, with highly-efficient portable equipment:

- FARO Laser Scanner Focus 3D, LEICA Laser Tracker AT401, CREAFORM Scanner 3D on optical 3-dimensional measuring machine MetraSCAN/C. Track, ROMER articulated measuring arm: Absolute Arm 7525SI – Range up to 300 m – Accuracy: ± 0.015 to 2 mm.

Additional services to match your needs:

- Proficient 3-dimensional measurement on site and in laboratories.

- Comprehensive management of complex reverse engineering projects.

- Selection of 3D measuring instruments suited to the specifications of your projects.

Your benefits

- Our metrology experts, members of standardisation bodies specialising in 3D measuring instruments, guarantee the method and results provided in a timely manner.

- Measurement uncertainties help to determine product conformity or non-conformity.

Case studies

Documentation

Scanning / Reconstructing your products in 3D