The approach proposed by Cetim is to identify the parameters for the success of your Additive Manufacturing based innovation.

Additive Manufacturing: supporting you throughout the value chain

Your expectations

Supply chain security, accelerated go-to-market procedures, manufacture of a critical component, etc.

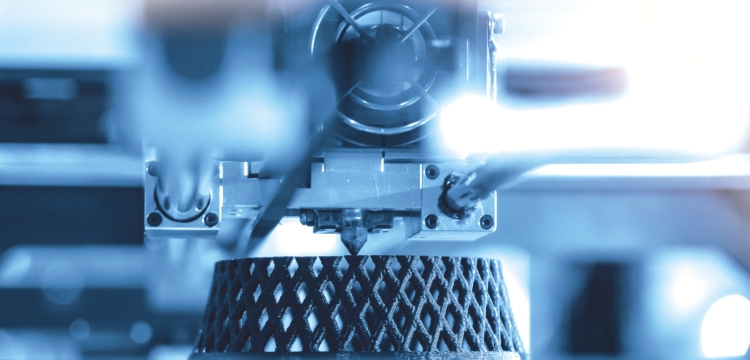

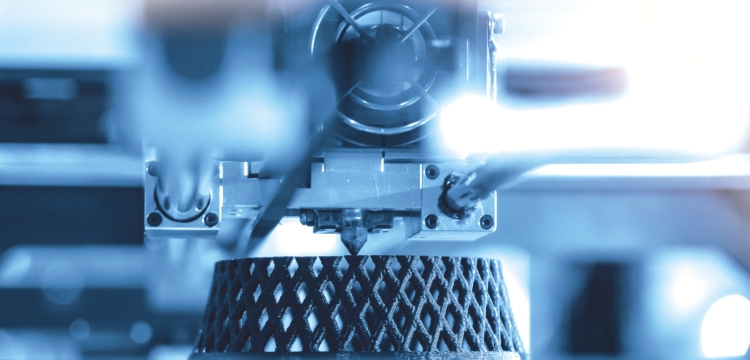

Additive manufacturing is an alternative to current processes and offers a solution to emergency situations, in particular thanks to its great flexibility and medium-sized production runs.

In this context, you want to:

- Determine the benefits of the additive manufacturing technology for your activity

- Produce your first parts

- Integrate additive manufacturing into your company

- Qualify your products

- Train your staff

Our solutions

Whatever your ambition, your project and your maturity level, Cetim offers pragmatic solutions geared towards your objectives and based on extensive knowledge of your business and the most advanced technologies.

- Diagnosis: we analyse the relevance of this technology to your field of application, overview of your sector of activity, tailored technical and economic feasibility study: your part / the selected material / the size of your production run.

- Design or redesign of parts to make the most of the technology: limitation of assemblies, topological optimisation of shapes, weight reduction, optimisation of surfaces (lattice structure, etc.), envisaged functional gains, study of new materials optimised for function and application.

- Evaluation of the considered solution: risks, adaptation costs and return on investment study.

- Testing and validation: development of the technical solution, assistance with the selection of powders and their sources of supply, manufacture of prototypes and production of proofs of concept (POC) on our platforms to help you master the technologies and the digital value chain, the sizing process and the testing procedures.

- Characterisation of materials and parts: non-destructive testing, testing methodology, dynamic and static testing, material health, etc.

- Project management assistance and integration of new resources into your environment: assistance in writing specifications, taking into account regulatory constraints (health, safety and environment, building codes, standardisation, etc.) and selection of equipment & machines, processing, finishing, inspection and cleaning.

- Change management and transfer of skills: assistance with installation and start of production; organisation of production and flow; environment; digital chain; supervision of and assistance to staff; training plan and knowledge management.

Your benefits

Only Cetim can mobilise independent experts with multidisciplinary skills.

You will benefit from tailor-made support across the entire value chain, from the feasibility study to industrial production, including upskilling of your staff with our Cetim Academy® training courses.

With Cetim’s experts, you will save time, secure your investments and tackle a wide range of additive manufacturing processes.