Choose the adhesive most fitted to your product

Choosing adhesives for multi-material assemblies

Your expectations

You want to:

• perform multi-material assemblies: integrate thermoplastic or thermosetting composites, glass, ceramic material, etc

• make productivity gains: reduction of assembling costs, simplification of machining tolerances, material reduction, etc

• provide your assemblies with additional functions: improve the integrity of your structures (no drilling or thermal damage), leak tightness, shock absorption, elimination of galvanic corrosion, etc

• impove the aesthetic of your parts

But you have to choose the product with the best cost-performance ratio within the framework of your application.

Our solutions

Cetim works along with you in all or part of the stages of your project:

Design

• assistance in specification drafting, supplier consulting, choice of products

• dimensioning/optimising the geometry of bonded joints: design, material and weight reduction with digital simulation tools

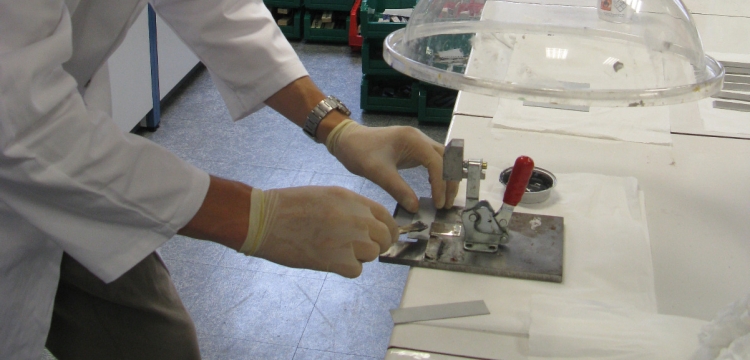

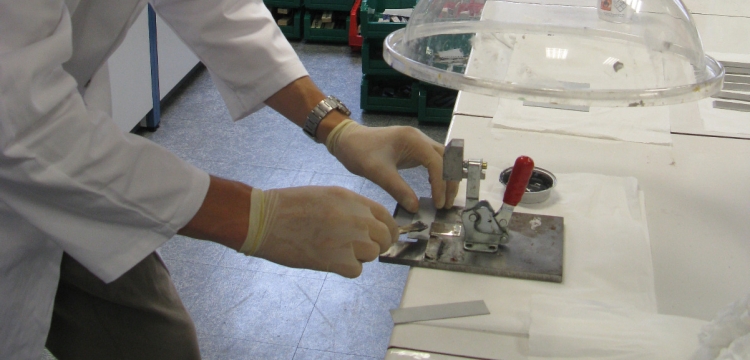

Implementation

• preparation of surfaces, application, determination of hardening time/temperature parameters and identification of other sensitive factors for your manufacturing process

• choice, dimensioning and installation of the equipment used

• technical-economical profitability sudy

Your benefits

• professional teams who master all best engineering practices from design to manufacturing process

• an independant specialist to help you evaluate your suppliers'performance

• testing means for implementation of adhesives and surfaces preparation (plasma torch, corona treatment, UV Lamp, sand spreader, etc.) to carry out quickly your feasability studies