Measure the mechanical properties of a metallic material

Mechanical properties of metallic materials

Your expectations

- You are looking for the right materials for a given application

- You want to characterise the compatibility of your materials with their environment

- You want to carry out tests to determine the specific mechanical properties of your material

- You want to determine the grade of steel corresponding to your material

- You are looking for reliable analysis and characterisation methods

- You want to ensure the traceability of your mechanical tests

Our solutions

A specialised team and resources in the field of test and characterisation of metallic materials :

- Static tensile tests to determine the mechanical properties (maximum strength, yield strength, module of elasticity, elongation, etc.), at room temperature, at high temperatures up to maximum 800°C, at low temperatures ranging to -196°C, in H2 environment.

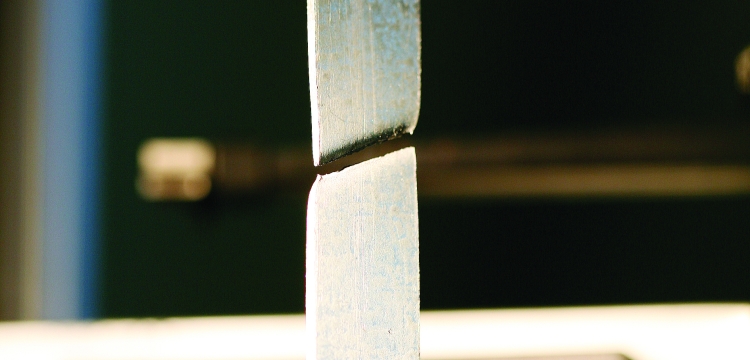

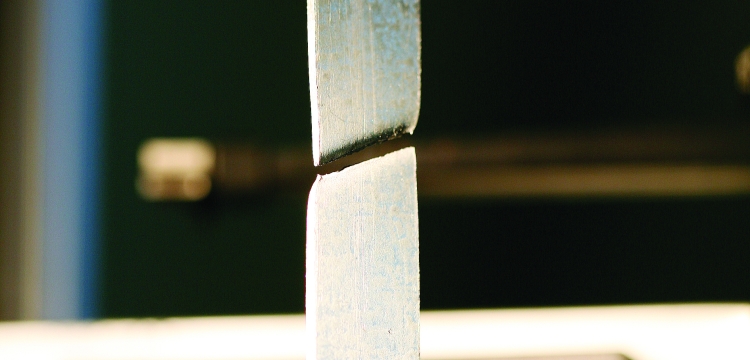

- Impact bending tests (measurement of notch impact strength) on previously notched metallic test specimen, between ambient temperature and -196°C,

- Hardness measurements (Vickers, Brinell and Rockwell B and C)

- Flattening, bending, flaring tests,

- Tests and characterisation of many metals and alloys, either on standardised tests specimens or on products (tubes, bolts, etc.)

- Characterisation of material ageing and prediction of service life

- Characterisation of the environmental compatibility of materials

ZOOM ON HYDROGEN

HyMEET, our technological platform dedicated to H2, provides mechanical engineering with resources and skills needed to master low-carbon hydrogen production, distribution, storage and utilization technologies. HyMEET combines an ambitious R&D program with a €25 million investment in resources dedicated to characterization and validation tests (up to 1000 bar and in a range of temperatures from deep cryogenics to high temperatures) as well as consulting and training.

Its activities are dedicated to:

- Characterizing the behavior of materials in contact with hydrogen

- Development of specific test methods

- Characterization of specific mechanical equipment and systems in severe hydrogen environments.

Our equipment enables:

- Mechanical characterization of materials using fatigue machines in a high-pressure hydrogen environment

- Control of sealing systems and plant containment, with test benches developed to study gas diffusion phenomena, resistance to rapid decompression and sealing performance under severe conditions

- The study of the ageing of test specimens in high-pressure autoclaves

- Tests under cryogenic conditions for the use of hydrogen in liquid form, with several cryostats fed by a helium-hydrogen liquefier

- Multiphysics tests with pressure, temperature and .... cycling.

- Manufacture of thermoplastic composite parts (tanks, tubes) by in-situ deposition and consolidation (in real time, with no further steps required) using our HySPIDE TP robotized cell.

Our specific services in the H2 environment:

- Mechanical characterisation of materials in a hydrogen environment (high pressure, gas mixtures and wide temperature range)

- Wide range of mechanical Fracture tests in H2 environments

- Support in selecting and choosing compatible materials for H2 applications

Your benefits

- Standardised mechanical tests or tests customised to meet your requirements

- Development of specific test protocols

- COFRAC accredited tests (accreditations COFRAC No. 1-1006 & No. 1-6755 - Scope available on www.cofrac.fr)

- Tailored and responsive service providing you with 6 local laboratories

- Access to the multidisciplinary skills of metallurgical teams to optimise your products

- Environmental characterisation resources (H2 and mixtures) over a wide range of temperatures and pressures

- Expertise relating to the whole of the usual metal processing (machining-bar turning, metallic additive manufacturing, welding, rolling, casting, forging, etc.).

- An independent laboratory and a major player in the aerospace, energy, rail, automobile, medical and naval sectors).