Complete service for the biomedical industry - From design to validation

Cetim: serving the biomedical industry

Your expectations

You would like to:

- Develop your innovative products to meet the needs of the market

- Characterise your parts or process with a view to optimising them

- Validate the performance of your implants as part of particular experimental references or standards.

Our solutions

High-performing environment for following the development of your medical devices, with skills in the following areas:

- Standard processes: forge, machining, shaping by distortion, etc.

- Innovative processes: high speed powder compacting, additive processes, etc.

- Materials: help in the choice of metals, plastics, composites, etc.

- Simulation (use of the leading major market codes).

- Mechatronics (development of a special sensor, functionalisation of your product).

Customised expertise for medical devices:

- Metallurgical and / or tribological analyses, characterisation of surfaces and coatings.

- Failure analysis (corrosion, wear, fatigue, etc.).

- Consulting services on cleaning technology, cleanliness check.

- Metrological testing, topographic analysis.

An entire team dedicated to implementing your tests:

- Design office integrated into the laboratory.

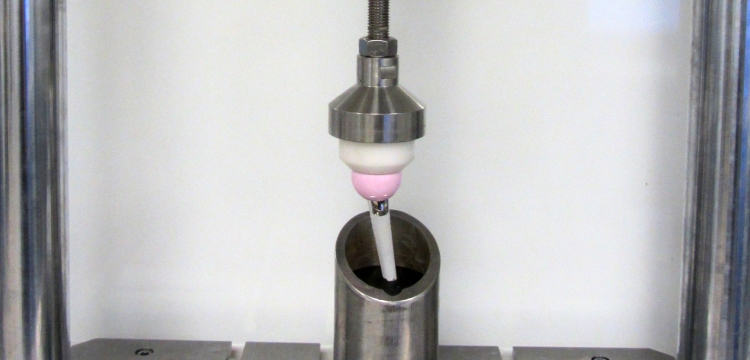

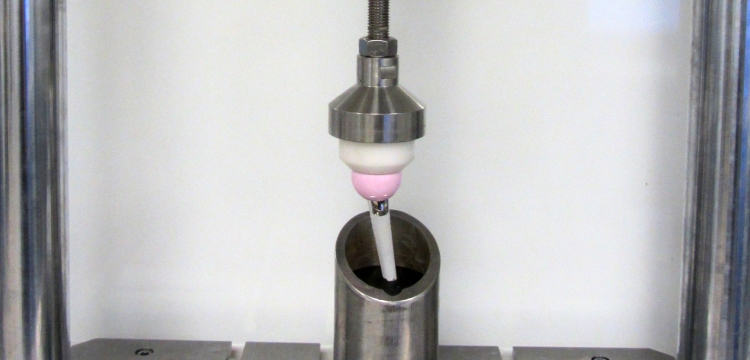

- Development of single or multi-axial fatigue, wear or static benches.

- Assistance in choosing an experiment protocol for implementing in accordance with the purpose of the test, in using and capitalising on the results.

- Static or fatigue tests on all types of implant: Hip, wear, knee, shoulder, spine, dental, etc.

Your benefits

Broad spectrum of skills adapted to solve your problems.

Comprehensive management and project monitoring adapted to your requirements.

Cofrac environment for tests on hip protheses and dental implant (accreditation COFRAC - No. 1-1006 - Scope available on www.cofrac.fr).

Case studies

Documentation

Cetim: serving the biomedical industry