products validation and optimisation from engineering to tests facilities

Test Engineering

Your expectations

You would like to:

- Establish the correlation between calculation and experiment.

- Characterise or validate your sub-systems, elements, components or parts under near-real conditions.

- Optimise an existing product.

Our solutions

An approach dedicated to engineering methodologies and test facilities:

- Support from formalising your requirements to analyse the tests.

- Skilled in the mechanical design of test benches.

- Skilled in fatigue post-treatment.

Design of special benches:

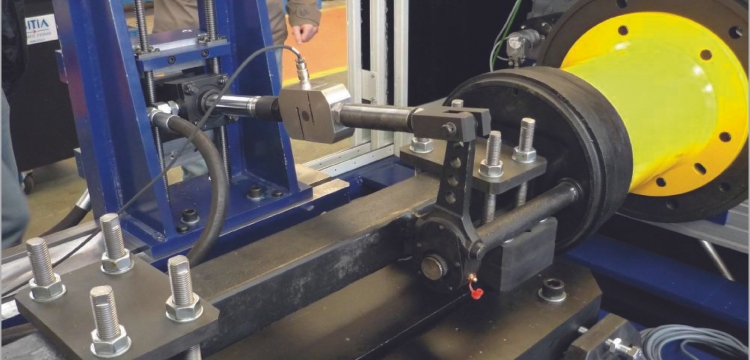

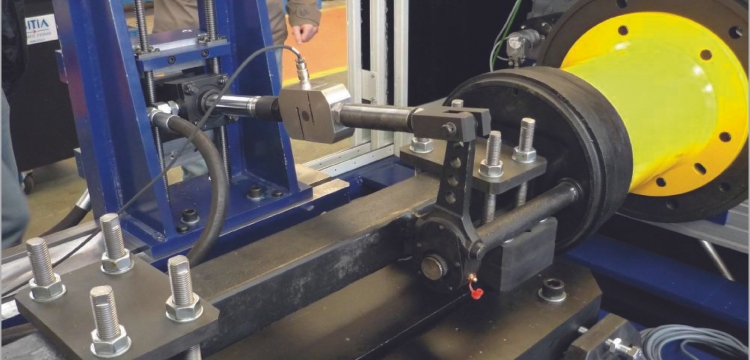

- Design, manufacture, acceptance and assembly of multi-axial static or dynamic test benches.

- Synthetic signals or simulation tests that can incorporate:

- Load or distortion control

- Temperature control

- Instrumentation (load, stress, temperature, pressure) - Using the results: analysis of sensor or gauge recordings, fatigue post treatment, fatigue reliability analysis.

Complex tests carried out on facilities ranging from 0.5 kN to 5,000 kN.

Non-destructive testing

Your benefits

- A multi-disciplined team

- More than 40 years’ experience in mechanical endurance testing.

- Comprehensive management of your requirements

- Project monitoring adapted to your demands

Case studies

Documentation

Test Engineering