In Hanover, PCI SCEMM, Cetim and Arts et Métiers (AMVALOR) will be unveiling a brand new electrospindle capable of collecting information at the site of machining real time during the cutting process

One technology…

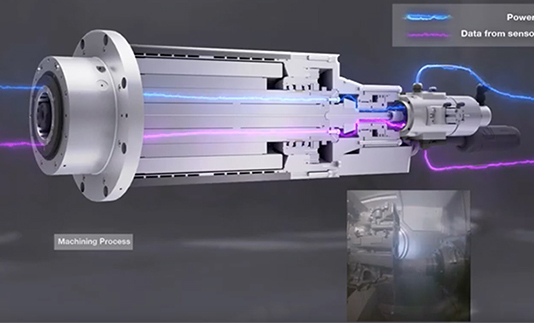

A world premiere! At the EMO trade fair 2019, from September 16-21, 2019, in Hanover (Germany), PCI SCEMM (stand Hall 12 stand A06) will be paving the way for smart machining through the latest technology with e-SPINDLE. Developed in partnership with AMVALOR and Cetim, this brand new electrospindle actually integrates all the equipment needed to monitor the cutting process as closely as possible and to react in real time. The integrated technology, allowing efficient management of sensors and actuators which are in a rotating frame of reference, is the result of collaborative work on smart machining by Cetim and the Arts et Métiers campus of Aix-en-Provence (INTELUS project, 2014-2017). The objectives are to improve productivity by optimising tool life and workpiece quality through e-SPINDLE’s ability to instantly correct processes that would otherwise not be recognized until the end of the machining cycle. E-SPINDLE’s cutting-edge technology allows for extraordinarily smart value-added machining including adaptive processes capable of modifying operating parameters in real time. Now that’s smart!

…three applications

At EMO the e-SPINDLE concept will present three smart machining applications:

- A tool holder for cutting process monitoring (forces, vibrations, pressure of the cutting fluid),

- A tool holder for adaptive vibration drilling, controlled with force threshold levels

- A honing tool holder with integrated “real time” measurement of the diameter of the workpiece, used for controlling the position of active parts (abrasive stones).

The e-SPINDLE concept paves the way for Smart Manufacturing utilizing IIoT and Industry 4.0.

A video presentation of e-SPINDLE is available on the PCI SCEMM YouTube channel.