Master and foresee risks means avoiding accidents, production stops and losses, which could put your company's existence in danger.

Cetim has developed a long experience and comprehensive knowledge in risk prevention and statutory compliance, and will efficiently contribute to help you control most industrial hazards, for the sake of your staff and organization.

Risk management and regulatory conformity

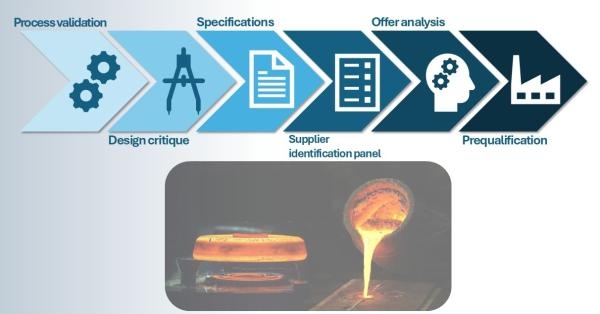

Our expertise covers the entire development process

PFAS: customized support from identification to substitution

Qualification of your forging and casting suppliers

Regulated substances and substitution

Residual life of structures and equipment

Machinery safety (CE marking)

Compliance of pressure equipment with manufacturing standards and codes

Asset Integrity Management (AIM)

Noise and vibration compliance at workplace

Noise and vibration compliance for machines and equipment

Storage tank frangibility study

Noise and vibration compliance in industrial environment

Management of industrial effluents